Virtual Design & Construction

EXPERIENCE YOU CAN COUNT ON

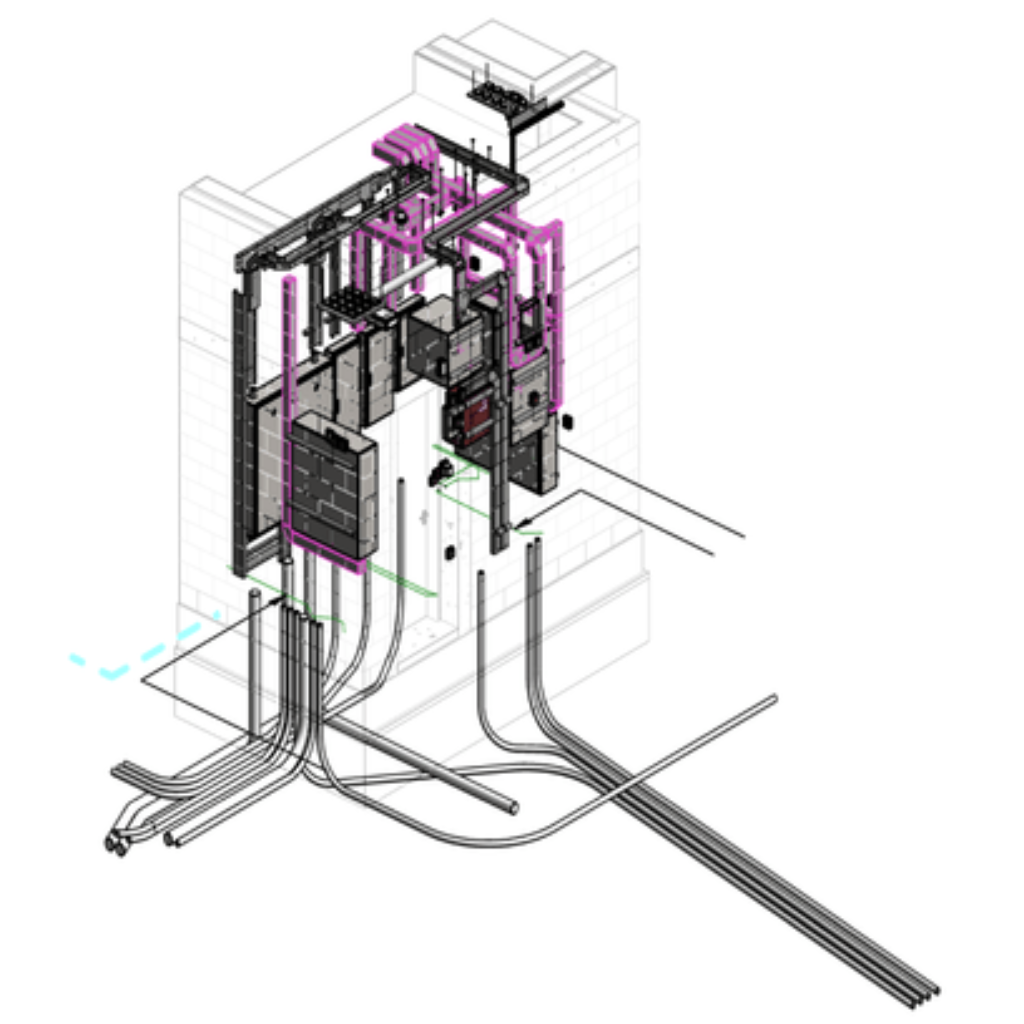

Our BIM-enabled workflow allows us to be involved with our projects from start to finish. We start right from the beginning by simplifying complex designs into easy-to-follow installation instructions with precise point-to-point layouts. With our cutting-edge technology, we essentially build a project twice: once in the virtual world, and a second time in the real world.

Using our extensive prefabrication space, we assemble as much of the project as possible before transferring it to the job site. The coordinates for virtually every pipe, conduit, duct, and hanger support are available with digital precision. Converting a virtual model into tangible construction reduces rework and waste, utilizes labor more efficiently, and creates a safer job site.

OUR Virtual Design & Construction SERVICES

Project Coordination

With a deep understanding of our clients’ needs, we develop comprehensive optimization solutions focused on achieving the greatest return on energy and financial investment.

Virtual Design & Construction (VDC)

We utilize advanced 3D modeling to coordinate underground and overhead installations with other MEP trades. From a coordinated model, we create build sheets for our fabrication shop, detailed installation drawings for the field, and layout points for our robotic total station.

Pre-Fabrication

Once your 3D model has been fully coordinated with other MEP trades, we create assembly build sheet drawings for fabrication. These components arrive on the jobsite with floorplan installation diagrams for “just-in-time” installation.

Point Layout

Many specialty trades use their own coordinates and work from an assumed or arbitrary location, which can lead to coordination issues and errors. Point layout eliminates this problem by establishing and sharing control points for the project, ensuring precise and accurate installations.